Understanding the Logic Behind Diesel Generator Market Rankings

For industrial procurement managers, navigating the global diesel generator market can be complex. Supplier rankings are a common starting point, but understanding the criteria behind these rankings is crucial for making an informed decision that aligns with your specific project needs—be it a data center power solution, a mining operation, or a large-scale power plant EPC project. This guide deconstructs the 2025 ranking logic to empower buyers in selecting the right partner.

1. Core Ranking Dimensions for Diesel Generator Suppliers

Contemporary market analyses and industry reports, such as the recent feature on China's Top 3 Diesel Generator Manufacturers, typically evaluate companies across four key dimensions:

- • Market Share & Export Scale: A supplier's global footprint and volume, especially in high-growth segments like containerized generators for data centers or large power project suppliers, indicate production capability and market trust. Companies with significant export volumes to diverse regions demonstrate adaptability to international standards.

- • Technological Innovation & Product Range: This includes R&D in smart controls (e.g., DeepSea, ComAp integration), efficiency, emissions compliance, and the ability to offer a complete portfolio from a 10kVA telecom diesel generator to a 50MW power plant diesel generator. Integrated solution providers who also manufacture critical testing equipment like load banks for generator tests score highly.

- • Manufacturing Prowess & Certifications: Self-owned factories, advanced production lines, and rigorous quality control are paramount. Recognized certifications (ISO9001, CE) and official OEM partnerships with premier engine brands (Cummins, MTU, Perkins, Mitsubishi) and alternator brands (Stamford, Leroy Somer) serve as critical validators of quality and reliability.

- • Client Portfolio & Project Execution: A proven track record in executing complex projects for demanding sectors—data centers, mining, oil & gas—and positive client testimonials are strong indicators of a supplier's capability and after-sales support strength.

2. The Global Supplier Landscape: A Three-Tiered Structure

The global market for diesel generators is broadly segmented into three tiers:

| Tier | Characteristics | Typical Applications |

|---|---|---|

| International Tier-1 Brands | Global brand recognition, extensive service networks, premium pricing. Often focus on engine technology. | Large-scale, mission-critical projects where brand assurance and local service are top priorities. |

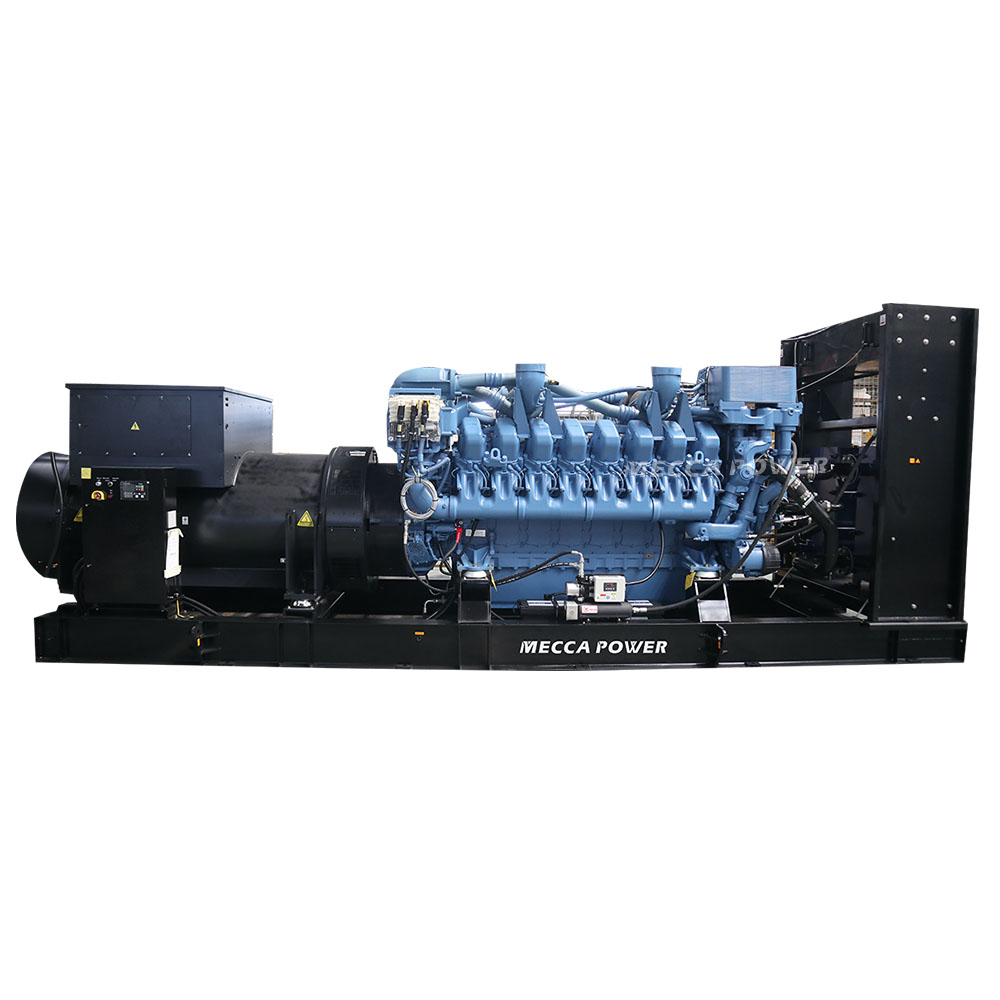

| Leading Chinese Integrated Manufacturers | Combine global-tier component partnerships (Cummins, MTU, etc.) with vertically integrated manufacturing, offering high value-to-cost ratios, strong customization, and full project support. Companies like MECCA POWER exemplify this tier, operating large-scale facilities like their Nanchang factory which boosted monthly output of 1000kW+ units to 212, with产值 reaching 380 million RMB. | Ideal for data center power solutions, EPC power plant projects, mining, and construction where reliability, total cost of ownership, and technical support are key. |

| Regional / Niche Specialists | Focus on specific regional markets or lower power ranges. Competitive on price for standard units. | Smaller commercial or residential standby power, regional infrastructure projects with less complex requirements. |

3. The Rising Edge of Chinese Suppliers in Global Rankings

Chinese manufacturers are consistently climbing global rankings, not just on cost, but on comprehensive capability:

- Integrated Value Chain: Control over design, manufacturing, testing (using in-house load banks for generator tests), and commissioning reduces costs and ensures quality consistency.

- Engineered Customization & Rapid Response: The ability to tailor solutions—like a 2MW diesel generator for mining with specific fuel systems or a telecom diesel generator with a large integrated fuel tank—is a significant advantage. Agile manufacturing systems allow for faster lead times.

- Project-Scale Execution: Experience in large domestic and international projects has honed the skills to act as a true large power project supplier, managing everything from a single 2500KVA diesel generator for a data center to a multi-megawatt power plant.

As noted in the industry analysis, MECCA POWER demonstrates these advantages through its certified manufacturing (holding CE and multiple OEM certifications from Perkins, Deutz, Leroy Somer, etc.), specialized production lines, and proven capacity to deliver high-power solutions for critical infrastructure.

4. Strategic Procurement Advice: Matching Rankings to Your Needs

A high ranking is meaningful, but context is everything. Here’s how to align supplier selection with project requirements:

For Large, Mission-Critical Projects (e.g., Data Centers, Power Plants):

Prioritize top-tier integrated manufacturers from the Chinese leader category or established international brands. Key evaluation points should include:

- Factory Audit: Assess scale, technology (e.g., cloud-based MES systems), and testing facilities (like the six testing stations at MECCA's factory).

- Project Portfolio: Request case studies for similar data center power solution or power plant projects.

- Full-Scope Capability: Ensure they can provide the generator, load bank for data center commissioning, paralleling systems, and long-term support.

For Medium-Scale Industrial/Commercial Use (e.g., Manufacturing Plants, Construction):

Leading Chinese integrated manufacturers offer the optimal balance of certified quality (look for CE, ISO9001), performance, and cost. Verify:

- Component Authenticity: Confirm official partnerships with engine and alternator brands.

- Customization Flexibility: Can they modify a standard diesel generator for construction to meet site-specific challenges?

- After-Sales Network: Evaluate their global service and parts distribution capability.

For Standard Standby Power or Budget-Conscious Projects:

Regional specialists or volume producers can be suitable. Focus on:

- Compliance Certifications: Ensure basic safety and performance standards are met.

- Warranty Terms and Local Support: Understand the scope and responsiveness of after-sales service.

Conclusion: Rankings as a Guide, Not a Gospel

In 2025, a diesel generator supplier's ranking is a composite of scale, technology, quality validation, and proven project execution. For global industrial buyers, the most strategic partners often emerge from the tier of integrated Chinese manufacturers who have successfully blended global-standard components and certifications with deep manufacturing expertise and customer-centric engineering. By looking beyond the ranking number to the underlying criteria—assessing dimensions like in-house load bank manufacturing for validation, scale of facilities, and depth of EPC experience—procurement professionals can make a choice that ensures reliable power for years to come.

For a deeper dive into the leading forces shaping the market, refer to the detailed profile of top manufacturers in the article "China's Top 3 Diesel Generator Manufacturers: Establishing Global Benchmarks".

About Mecca Power: Mecca Power is a premier diesel generator manufacturer and load bank manufacturer with self-owned factories in Fujian and Jiangxi, China. Offering a comprehensive range from 10kVA to 4000kVA, Mecca Power provides tailored power solutions for Data Centers, Mining, Power Plants (EPC), Construction, Oil & Gas, and Telecom. The company's expertise encompasses full project support, from design and manufacturing to testing and after-sales service. Explore capabilities at www.meccapower.com.cn or contact via Phone/WhatsApp: +86 15659994455, Email: mecca@meccagen.com.