In the high-stakes world of industrial power generation, selecting the right equipment is not just a purchase—it's a strategic decision impacting operational continuity, capital expenditure, and long-term reliability. For project managers, EPC contractors, and facility engineers, the choice between a high-power open-type unit like a 2.2MW diesel generator for data center and a fully integrated 3MW containerized diesel generator is a common yet critical dilemma. This comparison guide delves into the technical specifications, application scenarios, and strategic benefits of each, helping you make an informed decision for your next power project.

Understanding the Core Technologies: Open-Type vs. Containerized

Before we pit the 2000KW diesel generator against the 3000KW diesel generator in a container, it's essential to understand their fundamental design philosophies.

The 2.2MW Open-Type Diesel Generator: Power in Its Pure Form

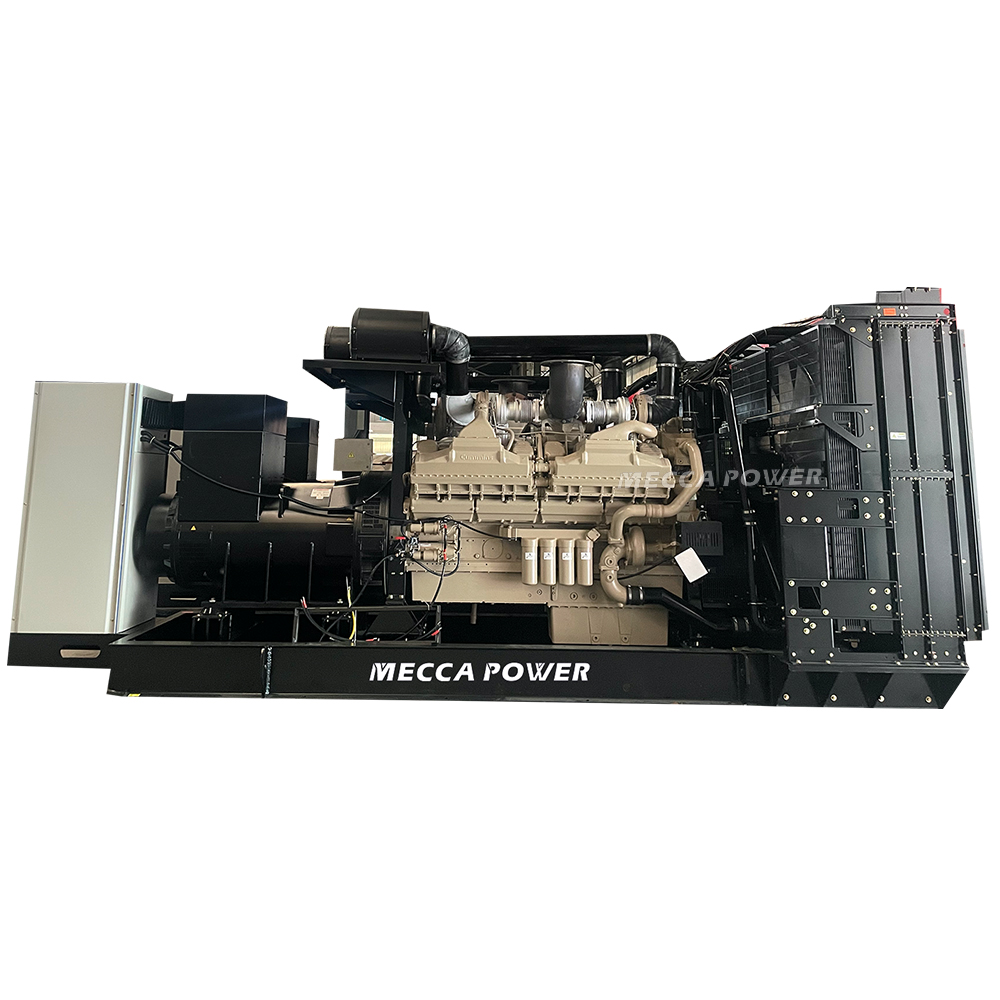

An open-type or base-frame generator is the core power generation unit without an integrated enclosure. A 2.2MW diesel generator in this configuration typically features a heavy-duty engine (from partners like MTU, Cummins, or Perkins) coupled with a high-efficiency alternator (such as Stamford or Leroy Somer). It's designed for installation within a dedicated plant room or shelter. This setup is often the go-to for EPA data center power generator requirements where space is allocated for mechanical rooms with separate acoustic and ventilation treatment.

A high-power Cummins-powered open-type unit, similar to configurations used for critical data center backup.

The 3MW Containerized Diesel Power Plant: All-in-One Resilience

A 3MW containerized diesel generator takes the entire genset and packages it into a weatherproof, sound-attenuated ISO-standard shipping container. It includes the engine, alternator, control system, fuel day tank, cooling system, exhaust silencers, and often paralleling switchgear—all pre-wired and tested. This turnkey solution is revolutionizing deployment for remote heavy-duty mining power generator needs and fast-track EPC contractor generator supplier projects.

A super silent generator housed in a container, offering plug-and-play functionality for diverse sites.

Head-to-Head Comparison: Key Decision Factors

| Decision Factor | 2.2MW Open-Type Diesel Generator | 3MW Containerized Diesel Generator |

|---|---|---|

| Deployment & Installation | Requires a constructed plant room. Installation is more complex, involving civil works, acoustic enclosures, and system integration on-site. Lead time to operational status is longer. | True turnkey power generator supplier solution. Delivered ready-to-run. Simply position, connect to fuel, power, and control lines. Dramatically reduces on-site installation time and cost. |

| Environmental Protection & Noise | Noise and weather protection must be provided by the building infrastructure. Achieving super silent generator standards requires additional acoustic engineering. | Built-in soundproofing and weather protection. Designed to meet strict noise level regulations (e.g., below 75 dB(A) at 1 meter) out-of-the-box, ideal for urban or noise-sensitive sites. |

| Mobility & Relocation | Permanent installation. Relocation is difficult and expensive, essentially a decommission and re-install project. | Highly mobile. Can be transported by truck, ship, or rail to new sites. Perfect for temporary mining camps, construction power (silent generator for construction), or disaster recovery. |

| Space Utilization | Can be more space-efficient in a dedicated, multi-level plant room, but requires that room to exist. | Has a larger footprint due to the container but contains everything within it. Eliminates the need to build a separate house, saving on civil costs. |

| Capital Cost & Scalability | Lower initial unit cost for the genset itself. However, total cost of ownership (TCO) rises with building, acoustic, and installation costs. Scaling up requires more plant room space. | Higher upfront unit cost, but a more predictable total project cost. For EPC contractor generator supplier projects, scalability is easy—just add more containers in parallel. |

| Maintenance & Service Access | Generally easier access in a spacious plant room for major overhauls, provided the room is designed for it. | Designed with service doors and panels. Can be more cramped for major work, but the entire unit can be swapped out quickly if needed for minimal downtime. |

Application Scenarios: Where Each Solution Excels

Ideal for the 2.2MW Open-Type Generator:

- Large-Scale Data Centers: As a dedicated EPA data center power generator, where multiple units are housed in a basement or separate building designed for power infrastructure, redundancy, and precise cooling.

- Permanent Industrial Plants: Manufacturing facilities, processing plants, or large commercial buildings with existing or planned central power houses.

- Major Power Plant EPC Projects: As part of a larger, fixed turnkey power plant supplier for 50MW project where generators are integrated into a custom-designed facility.

Ideal for the 3MW Containerized Generator:

- Remote & Rugged Sites: The undisputed best generator for mining site applications, especially in exploration or temporary phases. Also perfect for heavy duty generator for oil gas operations in deserts or offshore support.

- Fast-Track & Temporary Power: Large construction sites, film productions, festival power, and emergency response where speed of deployment is critical.

- Urban & Noise-Sensitive Backup: Hospitals, telecom hubs, or financial institutions in cities where space is limited and noise ordinances are strict.

- Modular & Scalable Projects: Ideal for utilities, independent power producers (IPPs), or EPC contractors needing to quickly add capacity in modular blocks.

The MECCA POWER Advantage: Engineering for Both Worlds

As a leading reliable diesel generator manufacturer and diesel generator OEM manufacturer, MECCA POWER doesn't just sell generators; we engineer power solutions tailored to the specific challenge. Our expertise allows us to guide clients to the optimal choice, whether it's a 2500KW diesel generator for a plant room or a 3MW containerized diesel generator for a mining camp.

Our self-owned factories in Fujian and Jiangxi provinces are equipped with dedicated lines for both open-type and containerized units. The Jiangxi facility, specializing in high-power sets above 1000kW, utilizes advanced digital tightening and cloud-based MES systems to ensure every industrial diesel generator meets the highest standards of quality and reliability. We hold OEM agreements with premier engine brands like Cummins, MTU, Perkins, and Mitsubishi, and alternator brands like Stamford and Leroy Somer, giving us the flexibility to configure the perfect power plant for any duty.

Inside MECCA POWER's advanced production workshop, where precision meets scale for both open-type and containerized gensets.

Our commitment is evidenced by certifications like CE, which underscores our dedication to international safety and performance standards. Whether you need a low fuel consumption diesel genset for cost-sensitive operations or a high altitude diesel generator engineered for thin-air performance, our R&D team and application engineers provide the necessary technical support.

Making Your Final Decision: Key Questions to Ask

- Is the site permanent or temporary? Temporary/remote = lean towards containerized.

- What is the timeline for becoming operational? Tight deadline = containerized offers faster deployment.

- What are the site's noise and space constraints? Tight space/noise limits = containerized is often simpler.

- What is the total budget, including civil works? Evaluate the Total Cost of Ownership, not just the unit price.

- Is future relocation or scalability a possibility? If yes, the modular nature of containerized plants is a significant advantage.

For complex projects, partnering with an experienced turnkey power generator supplier like MECCA POWER is invaluable. We can provide detailed feasibility studies, design support, and after-sales maintenance to ensure your power infrastructure, whether a single 2000KW diesel generator for data center or a multi-container power plant, delivers unwavering reliability.

Ultimately, the "better" choice depends entirely on your project's specific operational, financial, and logistical parameters. By understanding the core strengths of both the powerful 2.2MW open-type diesel generator and the versatile 3MW containerized diesel power plant, you are equipped to specify the solution that guarantees power resilience and operational efficiency for years to come.

To discuss your specific project requirements for a diesel generator wholesale supplier or a custom containerized diesel power plant, contact the engineering team at MECCA POWER today.

Website: www.meccapower.com.cn

Phone/WhatsApp: +86 15659994455

Email: mecca@meccagen.com