The Ultimate Buyer's Guide to Low Fuel Consumption Diesel Gensets

In an era of volatile fuel prices and increasing operational costs, selecting a low fuel consumption diesel genset is no longer a luxury but a critical business decision. For industries like data centers, mining, oil & gas, and large-scale construction, fuel efficiency directly impacts the bottom line and environmental footprint. This comprehensive buyer's guide will walk you through the key considerations, technologies, and features to look for when investing in a fuel-efficient industrial diesel generator.

Why Fuel Efficiency is Paramount in 2024 and Beyond

The global push for sustainability, coupled with rising diesel costs, has made fuel consumption a top priority. An efficient low fuel consumption diesel genset can reduce operational expenses by 15-30% over its lifetime. For a 2000KW diesel generator for data center running 24/7 as backup power, even a small improvement in fuel economy translates to massive annual savings. Furthermore, lower consumption means fewer refueling cycles, reduced carbon emissions, and enhanced compliance with environmental regulations, which is crucial for projects requiring EPA data center power generator standards.

Key Factors Influencing Diesel Generator Fuel Consumption

Understanding what affects fuel burn is the first step to making an informed choice.

- 1. Engine Technology & Tier Compliance: Modern engines from partners like Cummins, Perkins, MTU, and VOLVO incorporate advanced fuel injection systems (common rail), turbocharging, and electronic control modules (ECMs) that optimize fuel-air mixture in real-time. Look for engines meeting EPA Tier 4 Final or EU Stage V emissions standards, as they are inherently designed for better fuel economy and lower emissions.

- 2. Load Management & Smart Controls: A generator running at 70-80% of its rated load typically operates at peak efficiency. Advanced control systems from brands like DeepSea and ComAp, which MECCA POWER integrates, allow for precise load sharing, peak shaving, and grid paralleling, ensuring the genset runs in its most efficient zone.

- 3. Generator Design & Alternator Efficiency: High-efficiency alternators from Stamford, Leroy Somer, or Mecc Alte minimize electrical losses, meaning the engine works less for the same power output. This is a critical but often overlooked component in a low fuel consumption diesel genset.

- 4. Application-Specific Design: A super silent generator for an urban construction site has different cooling and acoustic requirements than a heavy-duty mining power generator for a high-altitude operation. Customization is key. For instance, a high altitude diesel generator requires engine derating and special turbocharger settings to maintain efficiency in thin air.

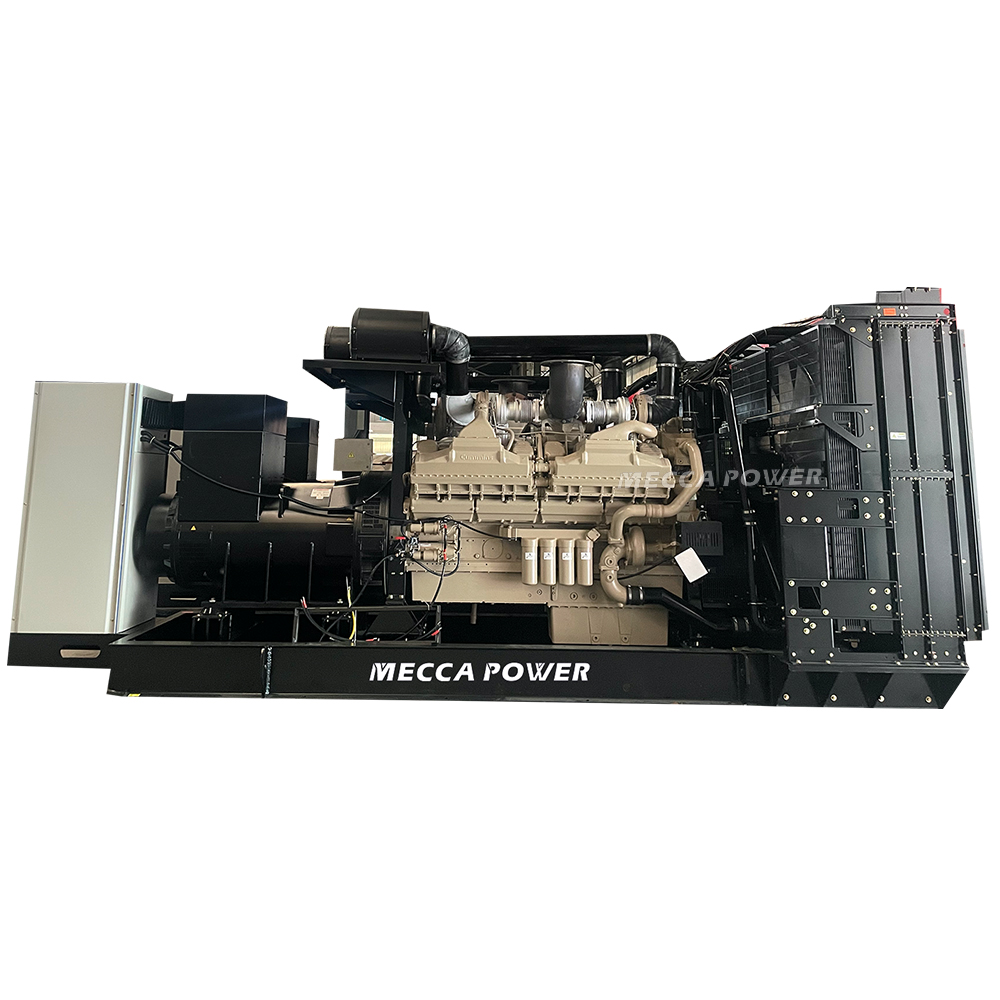

MECCA POWER's integration of high-efficiency Cummins engines is a cornerstone of their fuel-saving generator solutions.

Step-by-Step Guide to Selecting Your Fuel-Efficient Genset

Follow this checklist to ensure you partner with the right reliable diesel generator manufacturer.

Step 1: Precisely Define Your Power Needs

Calculate your total load (kVA/kW), considering starting currents of large motors. Determine if you need prime, continuous, or standby power. For a 50MW project requiring a turnkey power plant supplier, this involves detailed load analysis and potential future expansion. Undersizing leads to overload and inefficiency; oversizing leads to "wet stacking" and poor fuel economy.

Step 2: Evaluate the Manufacturer's Technical Capability

Look beyond the brochure. A true partner like MECCA POWER offers:

- Independent R&D: The ability to customize control logic for optimal fuel burn.

- In-House Testing: Their six testing stations with cloud-based data management verify fuel consumption claims under simulated real-world conditions.

- EPC Experience: A turnkey power generator supplier with EPC project experience understands system-level efficiency, not just unit-level.

Step 3: Scrutinize the Technical Specifications

Demand detailed fuel consumption curves at various loads (25%, 50%, 75%, 100%). Compare the guaranteed fuel consumption rate (g/kWh) at your expected typical operating load. For a 3000KW diesel generator for data center, a difference of 5 g/kWh can mean thousands of liters of fuel saved annually.

Step 4: Consider the Total Package & Ancillaries

Efficiency extends beyond the engine. Inquire about:

- Containerized diesel power plant designs with optimized airflow to reduce cooling fan power draw.

- Options for waste heat recovery systems.

- The efficiency class of the installed alternator.

- Smart remote monitoring capabilities to track fuel usage in real-time.

A super silent generator from MECCA POWER, designed for fuel-efficient operation in noise-sensitive environments.

Step 5: Verify Certifications and After-Sales Support

Certifications like CE and OEM partnerships (e.g., PERKINS OEM, Leroy Somer) are indicators of quality and adherence to international standards. A manufacturer's commitment to efficiency is reflected in their support. Does the diesel generator OEM manufacturer offer performance audits and tuning services to maintain peak efficiency over time? MECCA POWER's global after-sales network provides this crucial ongoing support.

MECCA POWER: Engineered for Efficiency

As a reliable diesel generator manufacturer and turnkey power plant supplier, MECCA POWER embodies the principles outlined in this guide. Their self-owned factories in Fujian and Jiangxi, featuring specialized production lines for containerized diesel power plant units and open-type sets, allow for precision engineering. Their partnerships with top-tier engine brands ensure access to the latest fuel-saving technologies. Whether you need a best generator for mining site that can withstand brutal cycles or a silent generator for construction in a city center, their design philosophy prioritizes low lifetime cost of ownership through superior fuel economy.

For a detailed consultation on selecting the most fuel-efficient industrial diesel generator for your specific application—be it a 2500KW diesel generator for data center or a heavy duty generator for oil gas project—reach out to their expert team.

Ready to Optimize Your Power Costs?

Contact MECCA POWER Today:

Website: www.meccapower.com.cn

Phone/WhatsApp: +86 15659994455

Email: mecca@meccagen.com

Let their engineers help you calculate your potential fuel savings and design a power solution that powers your project, not your fuel bills.