The Ultimate Guide to Specifying and Implementing Industrial Diesel Generators

In an era where power reliability is non-negotiable for industries ranging from hyperscale data centers to remote mining operations, selecting the right industrial diesel generator is a critical strategic decision. This isn't just about buying a machine; it's about investing in the operational heartbeat of your project. As a leading turnkey power generator supplier and diesel generator OEM manufacturer, MECCA POWER has distilled decades of engineering and field experience into this practical, step-by-step guide. We'll walk you through the entire process, from initial assessment to final commissioning, ensuring your power solution is robust, efficient, and perfectly matched to your needs.

Why This Guide Matters Now

The global push for digital infrastructure, coupled with the resurgence of resource extraction in challenging environments, has placed unprecedented demands on backup and prime power systems. Recent industry trends highlight a sharp increase in demand for EPA data center power generator solutions due to stricter emission regulations and for high altitude diesel generator units capable of operating efficiently in mountainous regions. Getting the specification wrong can lead to catastrophic downtime, inflated operational costs, and failed projects.

Step 1: Define Your Core Power Requirements

Before you even look at a product catalog, you must answer fundamental questions.

- Application: Is this for prime power (continuous operation), standby/backup, or peak shaving? A heavy-duty mining power generator for 24/7 ore processing has vastly different requirements than a super silent generator for an urban hospital backup.

- Load Calculation: This is the most crucial step. You must calculate the total kVA/kW requirement, factoring in:

- Starting currents of large motors (which can be 6x the running current).

- Future expansion plans. A 2000KW diesel generator for data center might suffice today, but will you need a 3000KW diesel generator for data center capacity in two years?

- Load type: Is it a steady, constant load or one with high harmonic distortion from variable frequency drives?

- Site Conditions: Altitude, ambient temperature, and humidity directly impact engine derating. A standard unit will lose significant power at high altitudes unless specifically designed as a high altitude diesel generator.

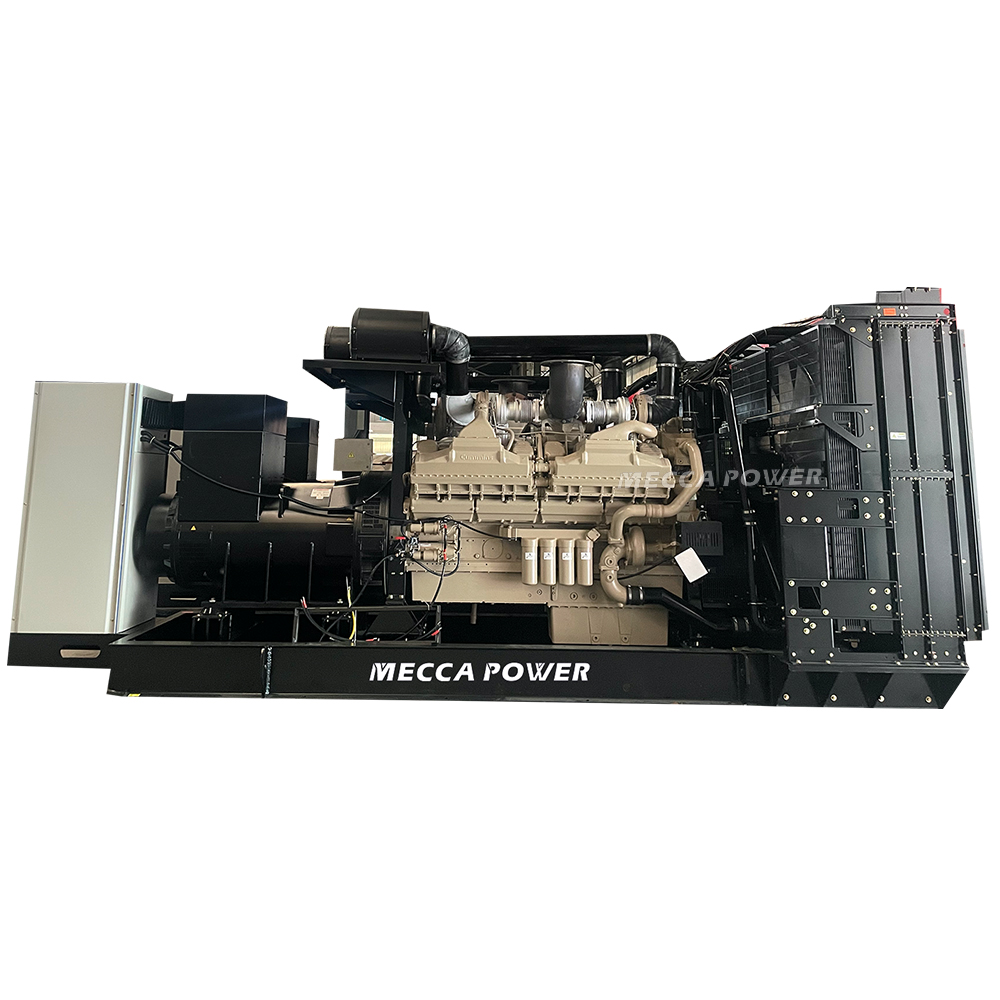

Fig 1: Precise load analysis is the foundation. MECCA POWER's engineering team uses advanced software to model load profiles for applications like data centers and mining sites.

Step 2: Navigate the Critical Engine & Alternator Selection

This is where partnering with a knowledgeable diesel generator wholesale supplier or OEM like MECCA POWER pays dividends.

Engine Brand & Tier Considerations:

We maintain strategic partnerships with premier engine brands to offer the best fit. Your choice depends on budget, local service support, and emission compliance needs (EPA Tier 2, Tier 4 Final, etc.).

- For Maximum Reliability & Performance: MTU, Cummins, and Perkins are top-tier choices for critical EPA data center power generator applications.

- For Cost-Effective, Robust Prime Power: Chinese engine brands, Mitsubishi, and Deutz offer excellent value for heavy duty generator for oil gas and construction sites.

- For Specific Projects: Volvo and Baudouin are often specified for marine and specific industrial applications.

MECCA POWER holds official OEM agreements with multiple brands, including PERKINS, Deutz, and Yuchai, ensuring genuine parts and factory-backed quality. Our certifications, such as the CE Certificate, are your assurance of international compliance.

Alternator Matching:

The alternator (generator end) must be correctly matched to the engine. Brands like Stamford, Leroy Somer, and Mecc Alte are industry standards. Key factors include voltage dip performance during motor starting and ability to handle non-linear loads.

Step 3: Choose the Right Configuration & Enclosure

The physical form of your generator set is dictated by its environment and use case.

| Configuration | Best For | Key Benefit |

|---|---|---|

| Open Skid / Canopy | Industrial plants, dedicated generator rooms with existing sound attenuation. | Lower initial cost, easier maintenance access. |

| Super Silent Generator (Enclosed Canopy) | Urban areas, hospitals, hotels, offices – anywhere noise pollution is a concern. | Noise levels as low as 60-75 dB(A) at 1 meter, aesthetic integration. |

| Containerized Diesel Power Plant | Extreme climates, remote sites (mining, oil & gas), large-scale turnkey power plant supplier for 50MW project solutions, and quick deployment. | All-weather protection, security, integrated fuel tanks and switchgear, easy transport. A 3MW containerized diesel generator is a complete, plug-and-play power station. |

Fig 2: MECCA POWER's super silent generators are engineered for noise-sensitive environments without compromising on power output.

Step 4: Integrate Advanced Control & Fuel Systems

Modern gensets are intelligent systems. The control panel is the brain. For critical applications, DeepSea or ComAp controllers with remote monitoring (SCADA/Genset Web Interface) are essential. They allow for real-time monitoring of parameters, fault diagnosis, and even predictive maintenance.

Fuel Efficiency is King: Operational cost is dominated by fuel. Specify a low fuel consumption diesel genset. This is achieved through:

- High-efficiency engines with electronic fuel management.

- Correct sizing (an oversized genset runs inefficiently at low load).

- Optional features like auto-start-stop based on load demand.

Step 5: Plan for Installation, Commissioning, and Lifelong Support

This is where the value of a true turnkey power generator supplier like MECCA POWER becomes undeniable. Our role extends far beyond manufacturing.

- Site Preparation Guide: We provide detailed civil layout drawings, foundation requirements, and ventilation/cooling specifications.

- Delivery & Rigging: We manage logistics, especially for massive units like a 2500KW diesel generator for data center.

- Commissioning: Our engineers perform on-site startup, load bank testing (essential to validate performance and "burn in" the engine), and system integration with your switchgear.

- Training & Documentation: We train your operators on routine maintenance and emergency procedures.

- After-Sales Service: As a reliable diesel generator manufacturer, we offer global support through spare parts supply, maintenance contracts, and 24/7 technical assistance. Our factories in Fujian and Jiangxi, with their advanced production lines and six testing stations, ensure consistent quality and readiness.

Fig 3: The backbone of reliability. MECCA POWER's state-of-the-art factory features digital tightening and cloud-based production management for traceable quality.

Case in Point: Specifying the Best Generator for Mining Site

A mining EPC contractor approached MECCA POWER for a prime power solution at a 3,500-meter altitude site. The challenges were clear: altitude derating, dusty environment, and requirement for 24/7 reliability. Our solution:

- Recommended a heavy-duty mining power generator with a turbocharged engine specifically calibrated for high altitude, delivering the required 2.2MW output.

- Configured it as a containerized diesel power plant with heavy-duty air filters and a larger radiator.

- Integrated a dual-fuel-tank system with automatic transfer for continuous operation.

- Provided a full turnkey package, including installation supervision and operator training on-site.

Conclusion: Partner, Don't Just Purchase

Selecting and deploying an industrial diesel generator is a complex, multi-disciplinary process. The lowest upfront cost often leads to the highest total cost of ownership. By following this structured approach and partnering with an experienced, vertically-integrated provider like MECCA POWER, you mitigate risk and secure a power asset that will deliver reliable performance for years to come.

Whether you need a single silent generator for construction or are managing a turnkey power plant supplier for 50MW project, the principles of thorough requirement analysis, correct technical specification, and professional implementation remain the same. Let our expertise guide your next critical power decision.

Ready to Engineer Your Power Solution? Contact the MECCA POWER team today for a detailed consultation and project-specific proposal.

📞 Phone/WhatsApp: +86 15659994455

📧 Email: mecca@meccagen.com

🌐 Website: www.meccapower.com.cn

🏢 Address: Room 11, 10th Floor, Building A1#, Cangshan Wanda Plaza, No. 272, Pushang Avenue, Fuzhou, Fujian, China.